Your Comprehensive Guide to Sourcing from a China Injection Molded Silicone Supplier

The world of manufacturing has evolved tremendously over the years, and one of the standout materials that have gained significant traction is silicone. Particularly, the China injection molded silicone supplier market has become a focal point for businesses seeking high-quality, cost-effective silicone products. This article delves into the multifaceted advantages of working with these suppliers, the processes involved, and how to make informed sourcing decisions that can elevate your business.

Why Choose Silicone?

Silicone is a versatile synthetic polymer known for its durability, flexibility, and resistance to extreme temperatures. The attributes of silicone make it a preferred choice for a variety of applications, including:

- Medical Equipment: Due to its biocompatibility and non-toxicity.

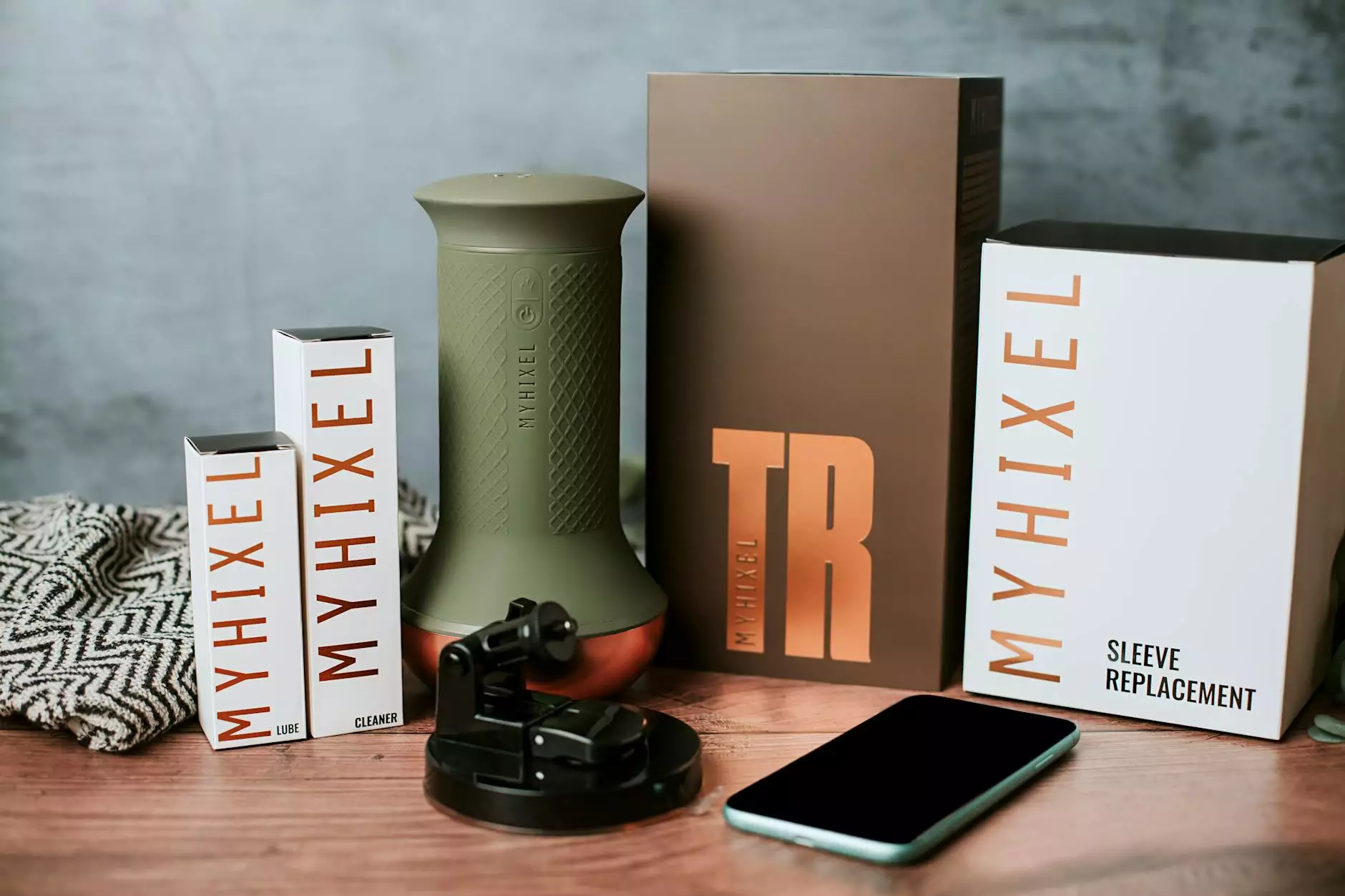

- Consumer Products: For items like kitchenware, toys, and personal care products.

- Automotive Components: Gaskets, seals, and electrical insulation.

- Industrial Applications: Such as machinery and heavy equipment.

The Advantages of Partnering with a China Injection Molded Silicone Supplier

When businesses consider sourcing silicone products, opting for a China injection molded silicone supplier can lead to outstanding benefits:

Cost Efficiency

One of the primary reasons companies look toward China for silicone products is the cost-effectiveness. Labor and production costs in China are typically lower, allowing suppliers to offer competitive pricing without compromising on quality.

Access to Advanced Technology

China has invested heavily in state-of-the-art manufacturing technologies. By collaborating with a China injection molded silicone supplier, businesses can leverage cutting-edge techniques, ensuring that the silicone products manufactured are sophisticated, precise, and tailored to specifications.

Quality Assurance

Working with reputable suppliers means you also gain access to stringent quality control processes. Many manufacturers are ISO certified, ensuring that all products meet both national and international standards.

Understanding the Injection Molding Process

Injection molding is a popular manufacturing method for silicone components. Understanding this process can help businesses appreciate the value they receive from their supplier:

Step-by-Step Injection Molding Process

- Design Phase: The process begins with designing the mold, which requires expertise and precision.

- Material Preparation: Silicone material is prepared and preheated to a suitable viscosity.

- Injection: The silicone is injected into the mold under high pressure, ensuring every detail is captured.

- Curing: The injected silicone then undergoes a curing process to harden and attain its final properties.

- Demolding: Once cured, the silicone products are removed from the mold for quality checks.

- Finishing Touches: This includes trimming, cleaning, and additional processes to achieve the required finish.

Selecting the Right China Injection Molded Silicone Supplier

When exploring various suppliers, businesses must consider several factors to ensure they choose the right partner:

Evaluate Their Expertise

Review the supplier’s experience in the industry and their specific capabilities with silicone products. It's essential to select a supplier with a proven track record.

Check Customer Reviews and Testimonials

Customer feedback can provide insights into the reliability and quality of a China injection molded silicone supplier. Look for case studies, testimonials, and user experiences to gauge satisfaction levels.

Quality Certifications

Assess the certifications held by the supplier, such as ISO 9001 or even specific industry-related certifications that denote adherence to quality standards.

Communication and Support

Effective communication is crucial in supplier relations. Ensure your potential partner is responsive and can provide support throughout the manufacturing process.

Challenges in Sourcing from China

While there are significant benefits, there are also challenges when sourcing from a China injection molded silicone supplier:

Language Barriers

Communication can sometimes be hindered due to language differences. Clear and precise communication is essential to avoid misunderstandings.

Time Zone Differences

Variations in time zones can pose challenges when quickly resolving issues or making urgent decisions.

Quality Fluctuations

Not all suppliers meet the same standards of quality. Conduct thorough due diligence to ensure consistency in product quality.

Best Practices for Effective Collaboration

To foster a productive relationship with your China injection molded silicone supplier, implement the following best practices:

Establish Clear Expectations

From the outset, define your requirements in detail, including specifications, timelines, and quality standards.

Regular Communication

Maintain consistent communication to track project progress and address concerns promptly.

Request Samples Before Production

Obtaining samples allows you to assess quality and ensure the final product meets your specifications before committing to large orders.

Continuous Improvement Feedback Loop

Provide feedback on your orders to help the supplier improve their processes and offerings continually.

Conclusion: Elevate Your Business with a China Injection Molded Silicone Supplier

Choosing to work with a China injection molded silicone supplier can significantly enhance your business’s product offerings, ensuring you benefit from quality, innovation, and cost efficiency. By leveraging advanced manufacturing processes and embracing strategic partnerships, your business can stay ahead of the competition. Regardless of the challenges that may arise, the right supplier relationship can lead your business towards sustainability and growth.

For companies within the realm of Music & Video, Musicians, and DJs, integrating high-quality silicone products into your offerings could open up new avenues and enhance user experience. Partnering with a reliable supplier can be a game changer for your operations.

In conclusion, whether you are looking to expand your product line, improve product design, or reduce manufacturing costs, sourcing from a trusted China injection molded silicone supplier can be the strategic move your business needs.